Customer

OHL – OHL Medioambiente Inima – SAV DAM

Country

Spain

Year

2011

Category

Bidding

Description

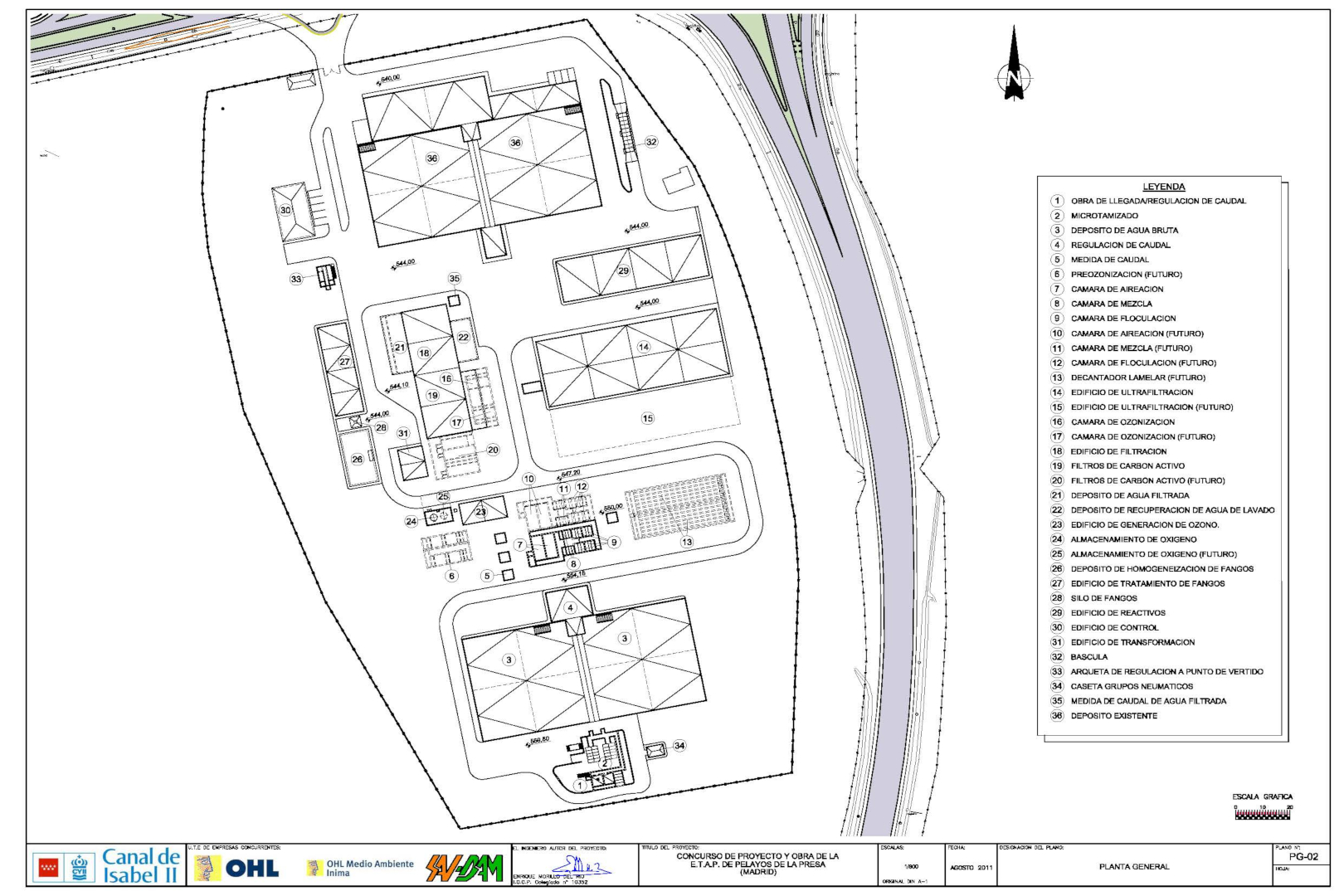

PELAYOS DE LA PRESA DRINKING WATER TREATMENT STATION (SPAIN)

Production capacity

43.200 m3/d

Characteristics

Water line formed by; New arrival work with flow control and regulation system, Raw water screening, Raw water regulating tank, Inlet flow regulation valve to the plant, Inlet flow measurement, Pre-oxidation chamber with atmospheric air for Iron oxidation and separation of floating elements, Calcium hydroxide dosage for pH adjustment and helps in the precipitation of iron and manganese, Chlorine dioxide dosage for the oxidation of the rest of iron and manganese, as well as other substances, Dosing Potassium permanganate for the oxidation of the remainder of the manganese, Dosing of powdered activated carbon for the absorption of organic matter and elimination of odors and flavors, Dosing of chlorine gas, Reagent mixing chamber, Dosing of poly aluminum chloride / alumina sulfate for the coagulation of dissolved or colloidal solids, Contact and reaction chamber, Clot formation, Ultrafiltration for retention of solids two from 0.04 microns, 1st stage 6 tanks. 2nd stage 4 tanks, Use of ultrafiltration permeate pumps to gain altitude to the next stage, Bypass system of the ultrafiltration process with gravity operation, Intermediate ozonation chamber, Active carbon filters, Contribution of residual disinfection capacity using chlorine gas and ammonia.

Sludge line formed by; Collection by skimmer of the floats in the previous aeration and their impulsion to the sludge homogenization tank, Homogenization tank of the rejection of the 1st ultrafiltration stage and incorporation into the 2nd ultrafiltration stage for concentration and recovery of clarification to the line of water, Collection and homogenization of activated carbon filter washing water in a regulating tank for washing water recovery, Lamination pumping and lifting of the activated carbon filter washing water to the rejection tank of the 1st ultrafiltration stage, with alternative to the head of the plant and sediments to a sludge homogenization tank, Homogenization tank for the rejection of the 2nd ultrafiltration stage and its pumping to the sludge homogenization tank, Homogenization and lamination tank for sludge flows and pumping to flotation, Preparation , storage and dosing of flocculant to thickening of sludge by flotation, Concentration of f slurries in flotation thickeners, Storage tank and homogenization of thickened sludge, Feeding of thickened sludge to sludge dewatering, Preparation, storage and dosage of flocculant to sludge dehydration, Dewatering, Pumping of dry sludge to storage silo, Storage of the dehydrated sludge.

Scope

- Descriptive memory.

- Sizing of the process.

- Hydraulic calculations.

- Structural calculations.

- Electrical calculations.

- Automation and control.

- Health and safety study.

- Blueprints

- Technical specifications of mechanical equipment, electrical equipment, automation and control

- Budgets